Silo Interior Cleaning

Product compaction, humidity, and electrostatic charge cause buildup on the internal walls.

Manual cleaning involves entering confined spaces with ATEX risk, high costs, and long downtimes.

Risks and consequences

- Contamination and loss of product quality.

- Reduction of the silo’s usable capacity.

- Risk of dust explosion (ATEX).

- Labor costs and production downtime.

Types of common waste

Caked flours, cereals, and sugars

Compacted mineral powders

Lumps of fats or oils

Corrosion encrustations

Silnet Solution:

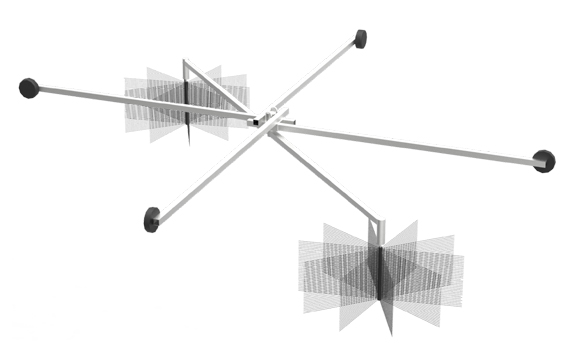

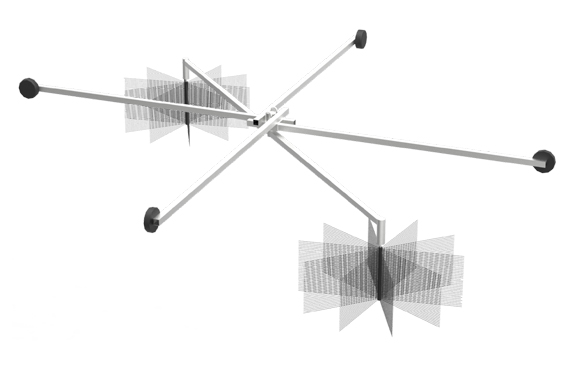

Automated cleaning

without operator entry

Silnet is inserted through the top opening and, using hydro-washing at 500 bar or pneumatic brushing, removes deposits in silos up to 20 m high and 4 m in diameter. ATEX version available.

Key Advantages of Silnet

- Avoids the presence of operators in confined spaces.

- Downtime reduced from days to hours.

- Compatible with wet or dry cleaning.

- Camera monitoring to validate cleaning.

- Modular aluminum system, easy to transport.

Frequently Asked Questions

Do I need to completely empty the silo?

YES, to guarantee the effectiveness and safety of the process.

Does Silnet work in explosive atmospheres?

We have an ATEX version with intrinsically safe motors and sensors.

What is the minimum entry opening required?

At least 350mm in diameter is required.

RELATED EQUIPMENT

Silnet

Silo cleaning.