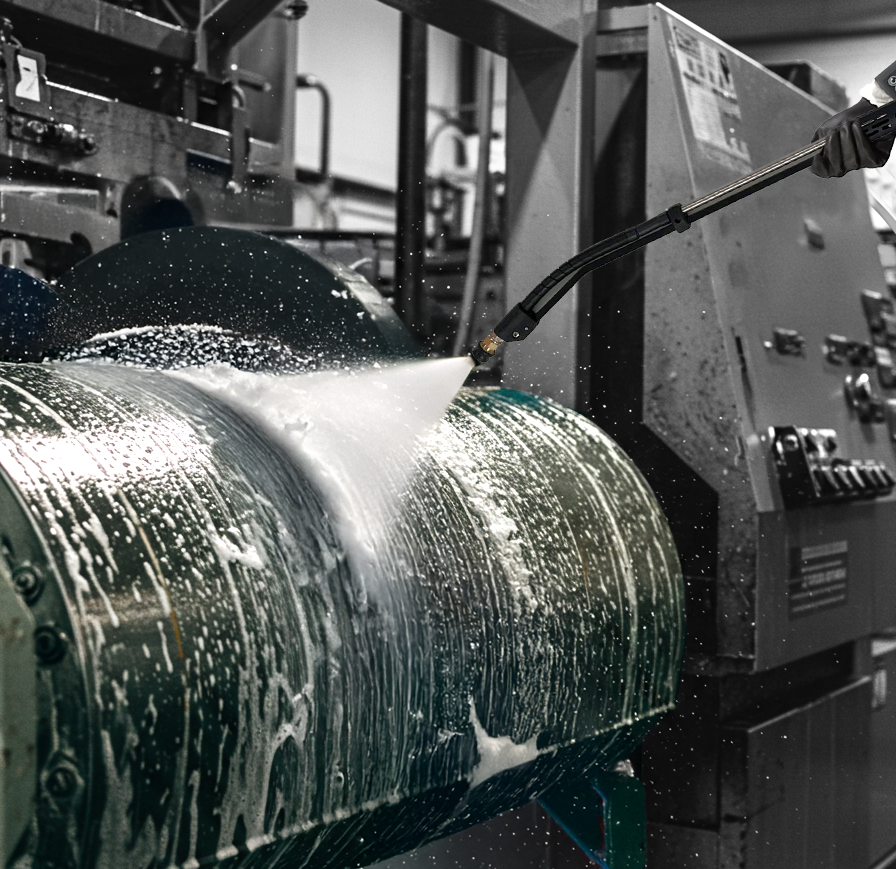

Industrial cleaning with active foam

Active foam cleaning is the ideal solution for removing greasy dirt in extraction systems and on greasy surfaces.

Thanks to its prolonged adherence, the chemical agent acts longer, dissolves the grease, and facilitates

a quick and safe rinse, reducing downtime and water consumption.

What is active foam cleaning?

Active foam is an exact mixture of water, air, and detergent formulated to generate dense bubbles that adhere to contaminated surfaces. By increasing the contact time, the chemical action penetrates the grease and emulsifies it without the need for mechanical abrasion.

Principle of adherence

and prolonged action

The microbubbles generate a stable film that does not run, even in vertical ducts, allowing the molecular bonds of the grease to break before rinsing.

Advantages for the extraction system and other surfaces

- Perfect adherence on vertical surfaces and ceilings: longer action time.

- Reduction of labor and cleaning times by 40%.

- Total elimination of biofilm and burnt grease without aggressive brushing.

- Lower consumption of detergent and water compared to traditional methods.

- Compatible with stainless steel, tile, technical plastics, and aluminum.

Foam Active process step by step

1

FOAM INJECTION

Projection of active foam on greasy surfaces, achieving adherence and chemical permanence.

2

MOLECULAR DISSOLUTION

In about 15 minutes, you can see how the white foam is dyed the color of the grease as it decomposes it.

3

WATER RINSING

Pressure rinsing that removes emulsified grease, leaving the surface clean and residue-free.

Frequently Asked Questions

Do you provide the necessary chemicals for cleaning?

Yes. We supply specific active foam detergents, compatible with our iFoam systems, guaranteeing the performance and safety of the process.

Do I need special protection to apply active foam?

The use of gloves and safety glasses is recommended.

Does the foam leave chemical residues?

No. After pressure rinsing, the surface is free of residues and suitable for food contact according to HACCP regulations.

RELATED EQUIPMENT

FHP1

High-pressure foam generator that provides everything necessary for cleaning and rinsing greasy surfaces in industrial environments.

FHP2

Foam and disinfection generator that works by connecting it to the high-pressure water network without the need for electrical connection or compressed air for cleaning industrial surfaces.