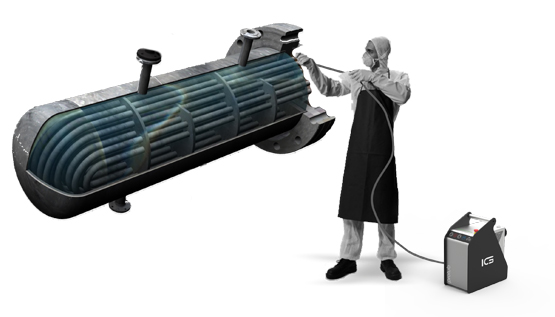

Cleaning of

heat exchangers

Restore the thermal efficiency of your equipment with solutions that eliminate scale and soot

without disassembling tube bundles or exposing operators to hazardous substances.

ICS offers the Protub system, also in an ATEX version, for cleaning heat exchangers quickly and safely.

Problems with

heat exchanger

cleaning

Over time, process fluids deposit carbonates, oxides, biofilm, and organic residues inside the tubes, reducing thermal transfer and increasing energy consumption. Limited access and narrow geometry complicate intervention and prolong plant shutdowns.

Consequence of dirt

- Loss of up to 30% of thermal performance.

- Increased fuel consumption and CO₂ emissions.

- Risk of corrosion under deposits and product leaks.

- Unscheduled shutdowns and high maintenance costs.

Types of common waste

Soot and combustion particles in boilers.

Calcium carbonate and other mineralized salts.

Bacterial biofilm in process water circuits.

Oxides and corrosion in oil and gas equipment.

Protub solution: rotary mechanical cleaning

Protub is a portable system that uses a rotating flexible shaft with nylon or steel brushes for internal diameters of 12 mm to 400 mm. Its speed regulator allows adjusting the friction according to the hardness of the deposit, and it can incorporate water injection to drag residues. The Protub‑ATEX version guarantees safe operation in classified areas.