Industrial extraction system cleaning

Smoke ducts, hoods, and extractors accumulate grease, soot, and particles that increase the risk of fire and reduce the efficiency of the system. An adequate cleaning and maintenance program is vital to guarantee safety and operational continuity.

Problems with extraction system cleaning

In industrial environments and high-volume kitchens, vaporized grease and particles become trapped in ducts and fans. Without regular cleaning, the accumulation decreases airflow, causes motor overheating, and creates ignition points that can trigger devastating fires.

Risks and consequences

- Fire in ducts and filters due to grease ignition.

- Fan malfunction and performance drop.

- Cross-contamination and odors in production areas.

Types of common waste in extraction systems

Volatilized cooking fats and oils

Metallic or chemical dust in industrial processes

Soot and particles from incomplete combustion

Acidic condensates that corrode the duct metal

Benefits of professional cleaning

- Reduction of fire risk and improvement of workplace safety.

- Recovery of extractor performance and lower electricity consumption.

- Extends the lifespan of fans and ducts.

- Compliance with safety and insurance audits.

RELATED EQUIPMENT

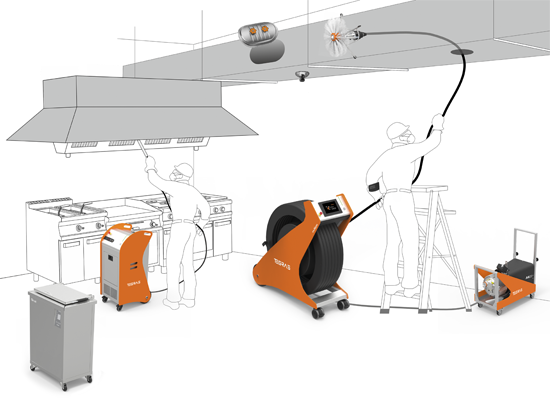

Tegras Range

For fast and safe cleaning, discover our TEGRAS, specifically designed for industrial extraction systems.