Cleaning of industrial

surfaces with laser

The short-pulse laser has become the definitive solution for selectively removing rust, paint, and contaminants without abrasion or chemicals. Discover how laser cleaning optimizes your maintenance and production processes, reducing costs and minimizing environmental impact.

What is laser technology cleaning?

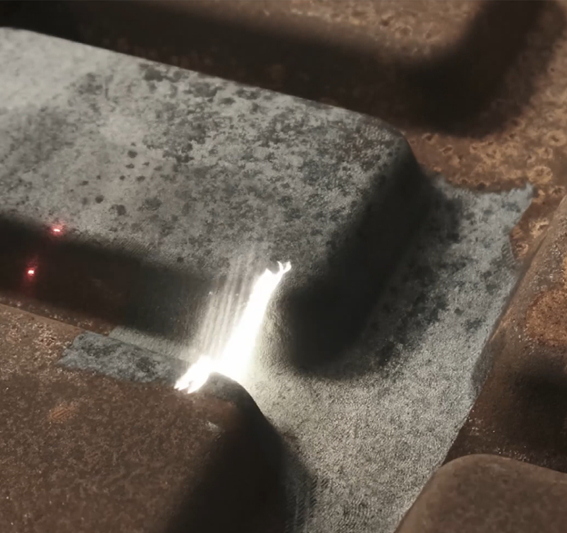

Laser cleaning uses concentrated light pulses that interact with the contamination layer, vaporizing or fragmenting it without affecting the substrate. Thanks to the high precision of the beam, we can safely and controllably remove oxides, carbonized grease, paints, and coatings.

Laser ablation principle

The laser pulse instantaneously heats the contaminating surface layer, causing its expansion and ejection (ablation) in the form of plasma or particles. The base material reflects much of the energy, which prevents thermal damage.

Advantages for the industry

- Non-contact and abrasion-free process: preserves tolerances and finishes.

- No chemical fuels or shot peening: reduces operating costs and waste.

- High selectivity: cleans specific areas without disassembling equipment.

- Safety on sensitive parts: compatible with steel, aluminum, composites, and molds.

- Automatable with robots and CNC systems for in-line production.

Measurable results

- Rust removal up to Sa 2 1/2 according to ISO 8501 in a single pass.

- Increase in cleaning speed of 70% compared to manual shot peening.

- Reduction of hazardous waste to zero, avoiding management costs.

Other industrial uses

- Surface preparation prior to welding or adhesive application.

- Paint stripping on bodywork and aeronautical structures.

- Cleaning of injection molds and dies without disassembly.

- Restoration of monuments and heritage without aggressive chemicals.

- Local removal of anti-corrosion coatings on pipes and tanks.

Frequently Asked Questions

Are consumables or chemicals required?

No. Laser cleaning is a dry process, without abrasives or chemicals, eliminating consumable costs and waste management.

Can it damage the metallic substrate?

No, the beam parameters are adjusted so that the energy is absorbed by the contaminating layer and reflected by the substrate, preventing fusions or microcracks.

Does it generate toxic fumes?

The vaporized contaminants are captured with HEPA extraction and filtration systems, ensuring a safe working environment.