Cleaning system for conveyor belts

BELTNET, CONTINUOUS CLEANING AND DISINFECTION SYSTEM FOR CONVEYOR BELTS

BELTNET uses high-temperature dry steam and synchronized vacuuming to remove product residue, allergens, oils, and biofilm, leaving the belt completely clean, disinfected, and dry without stopping production or requiring dedicated personnel.

• Standard cleaning module sizes for belts 40, 60, and 80 centimeters wide.

• Custom manufacturing possible for other belt widths.

• Possibility of connecting to existing plant steam.

BELTNET TECHNICAL DATA SHEET

| Electrical supply: Steam generator: Liquid vacuum: | 400V – 50Hz – 36kW 400V – 50 Hz – 3kW |

| Working temperature: | 175ºC |

| Recommended steam pressure: | 8 bar |

| Suction flow rate: | 330 m3/h |

| Sound level: | Less than 70 dB |

| Control system: | Electrical |

| Control panel: | Buttons on generator and vacuum |

| Belt dimensions: | For belts up to 1000 mm |

| Weight: | Depending on size |

| Working height: | Manually adjustable |

| Structure material: | Stainless steel and polyoxymethylene |

TECHNICAL DATA SHEET SG36 SATURATED STEAM GENERATOR

| Electrical supply: | 400V/50 Hz/3 phases |

| Nominal power: | 36 kW |

| Nominal steam pressure: | 0.8 MPa (8 bar) |

| Steam evaporation: | 51 kg/h |

| Steam temperature: | 175 °C |

| Pump power: | 0.55 kW |

| Control panel: | Intelligent control with LCD screen |

| Weight: | 180 kg |

| Dimensions: | 670 × 470 × 1280 mm 26,3 x 18,5 x 50,3 inches |

TECHNICAL DATA SHEET SV75 LIQUID VACUUM

| Electrical supply: | 400V/50Hz/3 phases |

| Maximum power: | 3Kw |

| Filtration surface: | 7000cm2 |

| Air flow: | 330m3/h |

| Sound level: | 69dB |

| Tank capacity: | 77L |

| Protection rating: | IP54 |

| Weight: | 115 Kg |

| Dimensions: | 550x550x140mm 21.65×21.65×5.51inches |

INDUSTRIAL APPLICATIONS

• Baking and pastries.

• Snacks, confectionery, and chocolate.

• Dry and dehydrated foods.

• Pharmaceutical and cosmetic industry.

• Manufacturing industry.

• Paint and varnish industry

BELTNET DRY STEAM TECHNOLOGY

High temperature (120 °C on the surface)

• Heat eliminates microorganisms and biofilm, even in hard-to-reach areas.

• Prevents the development of strains resistant to chemical products.

• Liquefies oils and fats, facilitating their extraction by vacuuming.

Extremely low humidity (5% water content)

• Allows cleaning near electrical and electronic components without requiring special protection.

• Significantly reduces water consumption and wastewater treatment costs.

• Leaves the belt dry and ready to operate immediately.

DRY STEAM TECHNOLOGY

• Heat destroys microorganisms and biofilm even in hidden areas.

• Prevents the appearance of resistant strains to chemicals.

• Melts oils and fats, facilitating their removal by vacuuming.

• Very low humidity (5% water).

• Allows cleaning near electrical components and electronics without the need to protect them.

• Drastically reduces water costs and wastewater management.

• Leaves the belt dry and operational instantly.

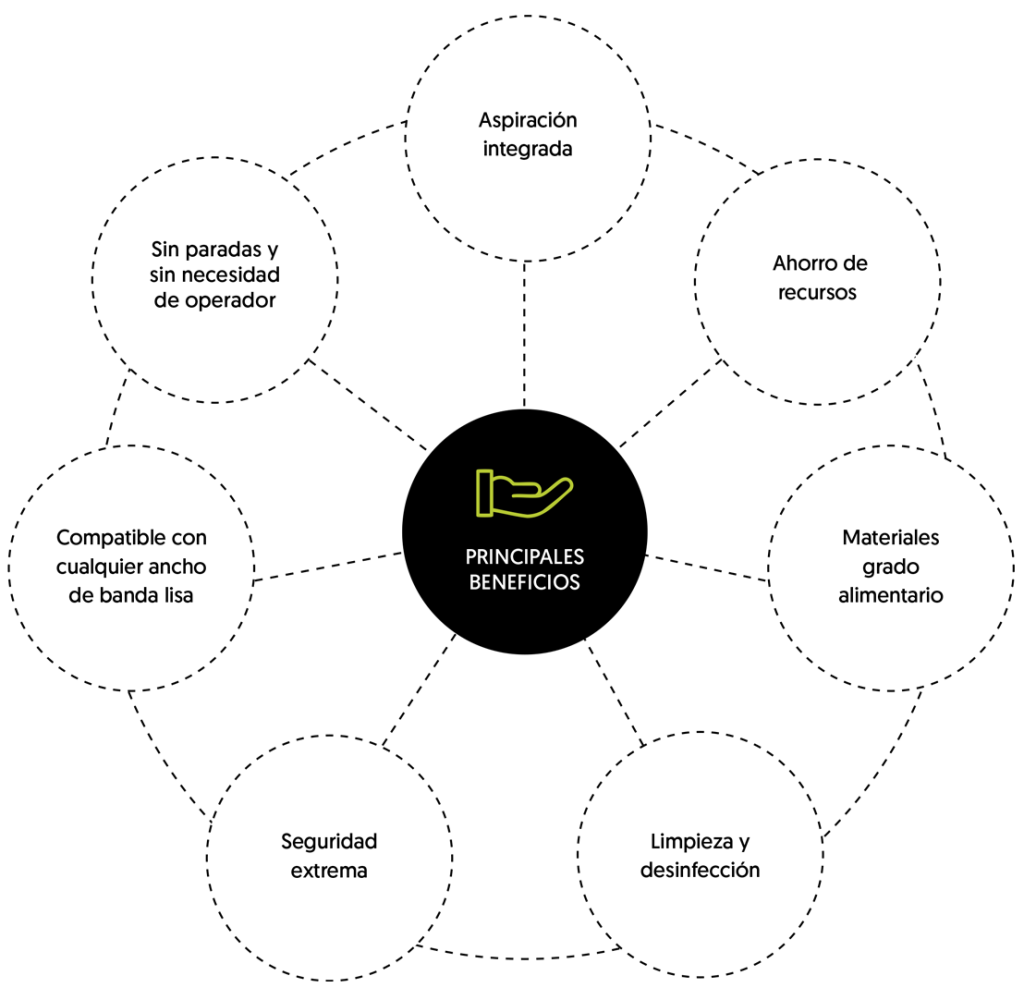

BENEFITS

• Without interruptions and without the need for an operator: automatic cleaning and disinfection during or after production, without human intervention.

• Integrated vacuum system: removes steam and contaminated water, leaving the belt clean, disinfected, and ready to use.

• Resource saving: up to 95% less water consumption compared to traditional methods.

• Compatible with any smooth belt width: does not require modifications to the conveyor frame.

• Maximum safety: steam-leak-free design. Handles, quick connections, and handling components with thermal insulation.

• Materials suitable for the food industry: stainless steel and polymers certified for the agri-food sector.

SYSTEM OPTIONS

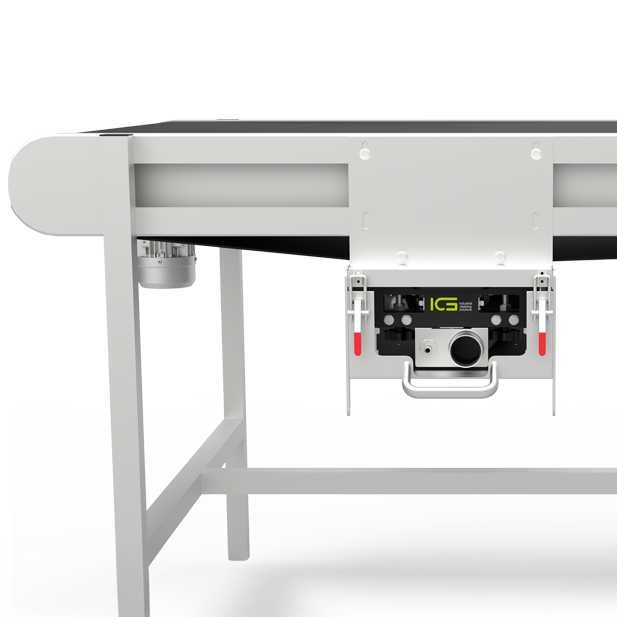

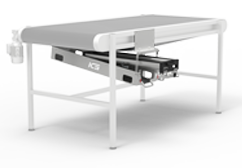

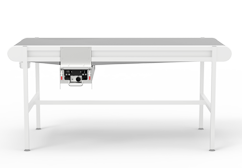

OPTION 1

BR40/60/80 cm and custom (Return)

– Head and support installed on the underside, in the return section.

– Continuous cleaning without interrupting production.

– The support is fixed to the belt structure.

– The head can be moved and used on other belts with support

installed on them.

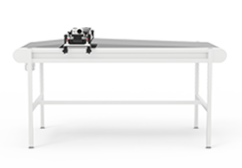

OPTION 2

BS40/60/80 cm and custom (Upper)

– Head located on the upper side of the belt.

– Quick system installation.

– Production is stopped to perform cleaning.

– Movable support and head from one belt to another.

PULL & PLAY

If required, the head can be easily moved from one support to another installed on a different belt.