Reviglass optimises the cleaning of its paint conveyor belts with Beltnet

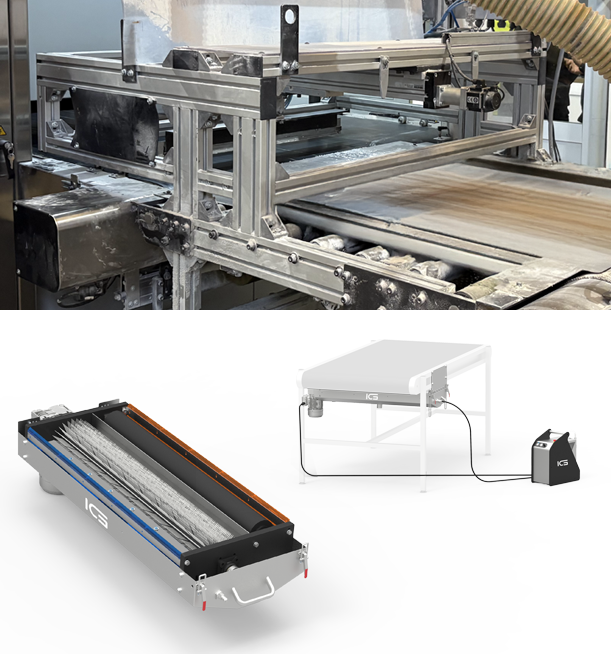

The challenge

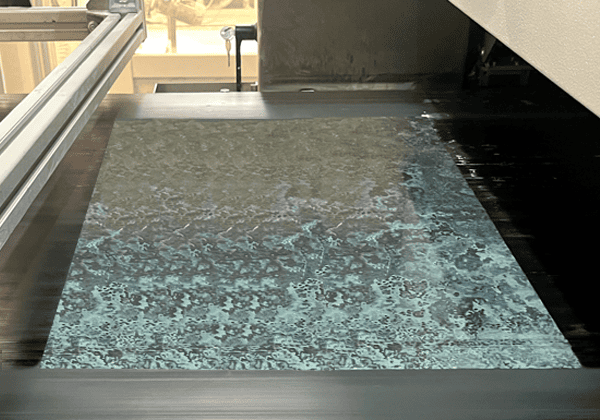

In the glass and mosaic industry, keeping conveyor belts clean on painting lines is a daily challenge. The accumulation of enamel and residue not only compromises product quality, but also leads to:

– Defects in finished parts

– Frequent stoppages for manual cleaning

– Risk of contamination and accidents

– Increased wear and tear and shortened belt life

Reviglass was faced with this scenario: a production line that needed continuity, precision, and a more efficient cleaning system.

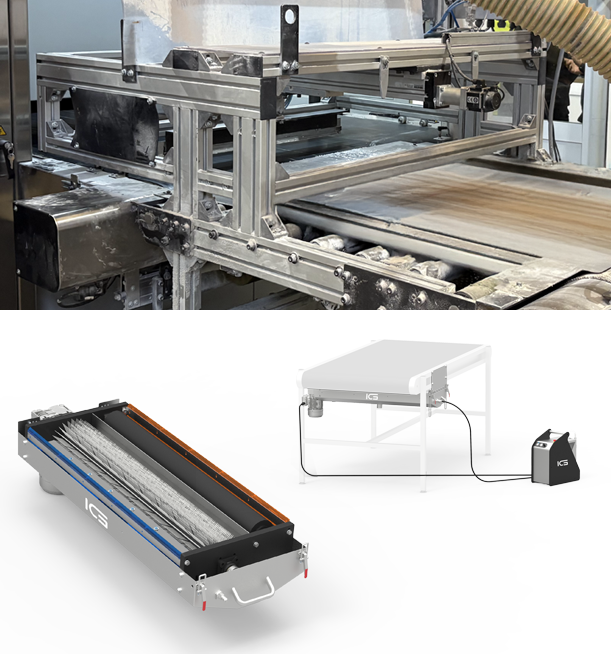

The solution

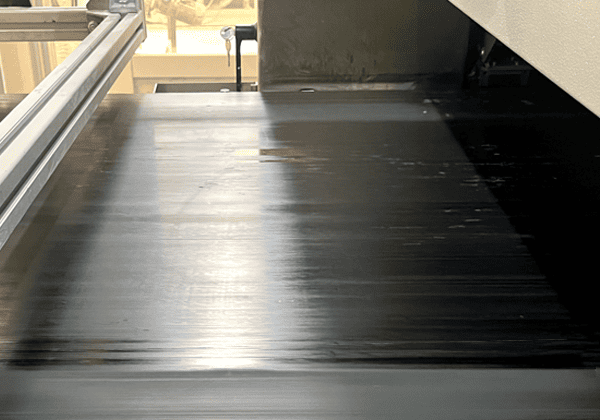

To meet this need, Reviglass incorporated Beltnet, the ICS automatic cleaning system designed to keep the conveyor belt spotless at all times, even during production. Beltnet removes fresh or semi-dry paint without damaging the belt and without stopping the process.

Results obtained

Thanks to this customised development, Reviglass has achieved:

– Clean belt throughout the entire working day.

– Drastic reduction in downtime due to manual cleaning.

– Less paint transfer to the product.

– Greater safety for the operator.

– Improved continuity and efficiency throughout the entire production line.